Before AI Transforms EPC Projects, Let’s Talk Foundations

Transforming EPC Companies with Digital Twin Technology

For years, Engineering, Procurement, and Construction (EPC) companies have excelled in managing the intricate workflows of capital projects. Yet, the scale and complexity of these projects often lead to challenges, such as scattered documents, redundant data, and inconsistencies across platforms.

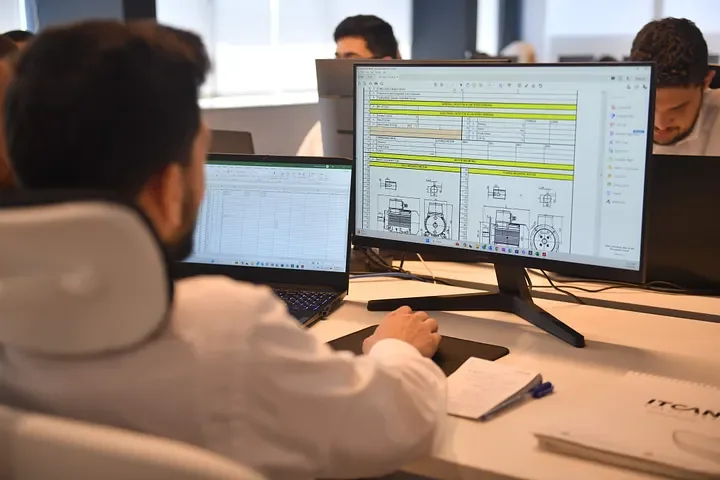

Engineers often spend nearly half their time searching for and verifying information scattered across various sources, such as spreadsheets, drawings, 3D models, laser scans, and text documents. This fragmented approach hampers productivity, inflates project costs, and results in delays to project timelines.

In an era increasingly driven by Artificial Intelligence (AI), EPC companies are turning to AI to streamline processes, accelerate projects, and enhance decision-making. However, AI's full potential can only be realized when it is built upon clean, integrated, and trusted data; without this foundation, even the most advanced AI systems struggle to deliver actionable insights and automation.

So, how can EPCs stay ahead in a world demanding faster, smarter project execution? The solution lies in Digital Twin technology. Acting as a dynamic, digital replica of physical assets and processes, Digital Twin technology consolidates fragmented data, integrates disparate systems, and provides a single source of truth. It not only ensures data accuracy for AI applications but also empowers teams with valuable insights and streamlined workflows.

Studies indicate that adopting a Digital Twin approach can enhance operational effectiveness by 10-20%, reduce expenses by 10-30%, and even boost revenues by 1-2%.

For both EPC companies and owner-operators, creating a Digital Twin that seamlessly integrates with existing systems transforms siloed data into actionable insights, enabling informed decision-making and proactive management.

By leveraging Digital Twin technology, EPC companies can unlock unparalleled efficiency, accuracy, and innovation, laying the groundwork for smarter, more sustainable project execution while maximizing the value of AI-driven tools.

The Challenges EPC Companies Face

EPC companies face significant challenges when managing large-scale projects. These include handling vast amounts of data, ensuring seamless coordination among various engineering disciplines, and maintaining consistency across workflows.

Here’s a breakdown of the most common challenges:

Fragmented Data: The lack of standardization across formats and systems complicates the process of correlating sources, validating information, and extracting valuable insights. Engineers often spend hours searching for documents, resulting in disorganized handovers and higher costs.

Revision Control: Handling vast amounts of information across disciplines requires precise management, especially when dealing with frequent revisions. Tracking multiple versions of datasheets and ensuring teams are aligned with the latest, approved versions can be time-intensive and lead to miscommunication, rework, or delays.

Risk Management: Conventional approaches to risk management often fall short in addressing the complexity of modern capital projects, allowing issues to go unnoticed until they escalate into larger problems.

Sustainability Pressure: Balancing environmental responsibilities with cost and time constraints adds another layer of complexity.

Lack of Connectivity: The use of multiple disconnected tools and software by various stakeholders creates silos, limiting access to critical project information.

Tag Management: Maintaining data accuracy, ensuring seamless integration across systems, and managing the complexity of tracking and updating large volumes of tags throughout the project lifecycle.

So, what’s the solution? How can EPC companies overcome these roadblocks and embrace the future?

A New Era with Intelligent Engineering

Today’s EPC firms have the opportunity to move beyond outdated methods by adopting a Unified Engineering approach.

Imagine an integrated system where every aspect of a project—from design and engineering to procurement and construction is seamlessly connected and consolidated.

Digital Twin technology equips EPC companies with Intelligent Engineering solutions to streamline project management and address complex challenges effectively.

With these solutions, data is standardized, contextualized, categorized, tagged, and validated, ensuring it is accurate, structured, and ready for operational use. This process not only enhances ongoing project management but also ensures a smooth and seamless handover at the project's conclusion.

So how does this process break down into actionable steps?

Given that 51% of companies still rely on manual data transfers and 13% of working hours are lost searching for information, the importance of tagging and organizing equipment data cannot be overstated. This step simplifies and accelerates access to insights, with standardized equipment datasheets ensuring critical information is well-organized, easily accessible, and optimized for efficient use. This approach reduces time spent searching for data and minimizes errors and miscommunication.

Validated data is then integrated into a unified data hub, providing teams with clean, structured, and easily navigable information. This enables faster decision-making, enhances collaboration, and ensures projects remain on track; in fact, another study estimated that digital twins help industrial organizations achieve 10-30% increase in planning efficiency and reduce staff hours by 15%, thanks to advanced visualization tools that provide a clear view of project progress, enabling a better proactive risk management process.

Another significant benefit is that these solutions support sustainable project execution by guiding EPC companies in selecting materials and methods that minimize environmental impact while maintaining quality and cost-effectiveness.

In short, Intelligent Engineering solutions provide EPC companies with the tools they need to tackle complex challenges, enhance efficiency, and deliver better outcomes at every stage of the project lifecycle.

Conclusion

The Future is Unified

In an industry where precision and coordination are essential, adopting digital tools like Digital Twin isn’t just an option—it’s essential for staying competitive and meeting modern project demands.

By addressing challenges such as fragmented data, inefficient collaboration, and sustainability demands, these solutions enable seamless data management, rigorous revision control, and enhanced project accuracy.

Ready to see the impact? Explore how Intelligent Engineering is transforming workflows and delivering success in EPC projects.

References: