Empowering F&B Factories with Digital Twins

Before you fix the machine, fix the map. Data clarity is the new operational edge

What if the biggest threat to your plant’s performance wasn’t equipment failure but the invisible chaos of unstructured data?

One of the most common and underestimated barriers to operational excellence in the Food and Beverage industry is scattered and unstructured asset data. In fact, studies show that engineers spend up to 30% of their time searching for information, and more than 70% of industrial data remains unused after it's collected.

This fragmentation not only slows down efficiency but also creates significant risks to maintaining a reliable operating system.

What’s Causing Fragmented Data?

In the food and beverage industry, many companies still rely on legacy documentation—paper records, disconnected spreadsheets, scanned PDFs, and unlinked technical documents. Over time, this leads to:

Legacy Documentation: Paper trails and archived PDFs that don’t reflect current updates.

Scattered Datasheets: P&IDs, E&ICs, asset manuals, equipment datasheets, etc. all stored in silos, often not updated or cross-referenced.

Outdated Information: Physical changes on-site aren’t reflected in digital records.

Lack of Digital Integration: No single system to view, track, or analyze asset data.

This system doesn't just disrupt teams; it affects performance, reduces visibility, and introduces unnecessary downtime and risk.

The Cost of Unstructured Data

Let’s put it into perspective.

The impact of unstructured and outdated data is not just a technical inconvenience—it’s a significant financial burden. According to Aberdeen Research, unplanned downtime can cost manufacturers an average of $260,000 per hour. IBM reports that poor data quality is responsible for over $3 trillion in annual losses across U.S. businesses, while McKinsey notes that engineers in industrial sectors spend between 20% to 40% of their time simply searching for asset information. Now, consider the cumulative effect of these inefficiencies across hundreds of assets, spread over multiple facilities, all operating under strict production deadlines. The result is a substantial drain on productivity, profitability, and operational resilience.

So, How Do We Fix It?

Addressing the asset data gap begins with a grounded, field-verified approach—literally.

The process begins by conducting thorough on-site verifications where engineers walk down the physical site, marking up P&IDs, E&ICs, and schematics to ensure they reflect the actual plant configuration. In many legacy plants, it’s not uncommon to find that a significant number documents are outdated or incomplete, leading to serious safety and performance risks.

During this phase, each asset—whether it’s a valve regulating critical flows, a temperature sensor on the production line, or an electrical panel powering operations—is physically identified, tagged, and cross-referenced with existing data. This is followed by documentation standardization, which involves unifying formats, updating obsolete datasheets, and aligning all records with current engineering standards. Once assets are accurately tagged and verified, the next step is drafting and converting new, accurate versions of P&IDs, E&ICs, and equipment datasheets that reflect the true, as-built state of the plant.

The real transformation, however, comes with digital integration when all this structured, verified data is brought into a centralized digital hub. Instead of teams working in silos with conflicting versions of data, everyone—from junior engineers to leads and higher management can access the same reliable source of truth. This eliminates miscommunication, simplifies troubleshooting, and provides accelerated access to critical insights.

hen one global beverage manufacturer consolidated its scattered documents into a single digital platform, they saw a 25% boost in productivity—a direct result of improved maintenance response and faster access to information

Another leading food and beverage company documented an 84% reduction in production downtime following the implementation of a centralized digital system

The result? Smarter decisions, faster responses, and a scalable foundation for technologies like AI to thrive.

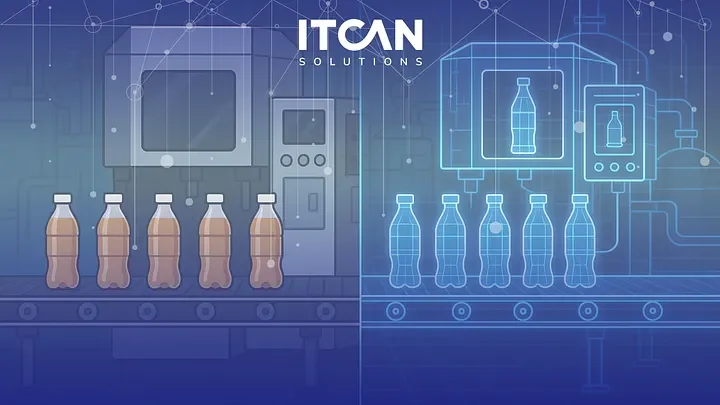

From Structure to Simulation: Enabling the Digital Twin

This is where Intelligent Engineering takes the lead. It’s not just about digitization—it’s about transformation. Intelligent Engineering converts fragmented documents into actionable data and static assets into dynamic digital entities. By adopting a tag-centric approach, every asset is embedded with context: specifications, real-time conditions, historical performance, and predictive behaviors.

These contextualized assets form a connected digital ecosystem—an environment where Digital Twins can thrive. The result? A well-structured, interactive model of your facility that continuously learns and adapts. Engineers can simulate scenarios, benchmark performance, and optimize operations before disruptions occur. And with every interaction, the system becomes more intuitive, more insightful, and more aligned with operational goals.

Because the next step isn’t just digitization—it’s intelligence. And that’s where the future is.

So, Ask Yourself—Can You Really Trust Your Asset Data?

If the answer isn’t a confident yes, you’re not just losing time. You’re losing money, insight, and opportunity.

It’s time to eliminate the gaps, centralize your data, and unlock the full potential of your operations—with Intelligent Engineering, Digital Twins, and a partner who understands your challenges.

Let’s talk about building your digital foundation.

Book your demo now

References

Aberdeen Research on unplanned downtime costs:

IBM's estimate on the cost of poor data quality:

ArticleCube+1Cottrill Research+1

McKinsey's findings on time spent searching for information:

Case study on digital tagging reducing equipment search time:

Case study on document consolidation reducing production downtime: